Αυτή η συζήτηση των μέσων φίλτρου προορίζεται να είναι μια συγκριτική σύνοψη των προϊόντων που χρησιμοποιούνται συνήθως σε οικιακές και εμπορικές εγκαταστάσεις διήθησης υπό πίεση.

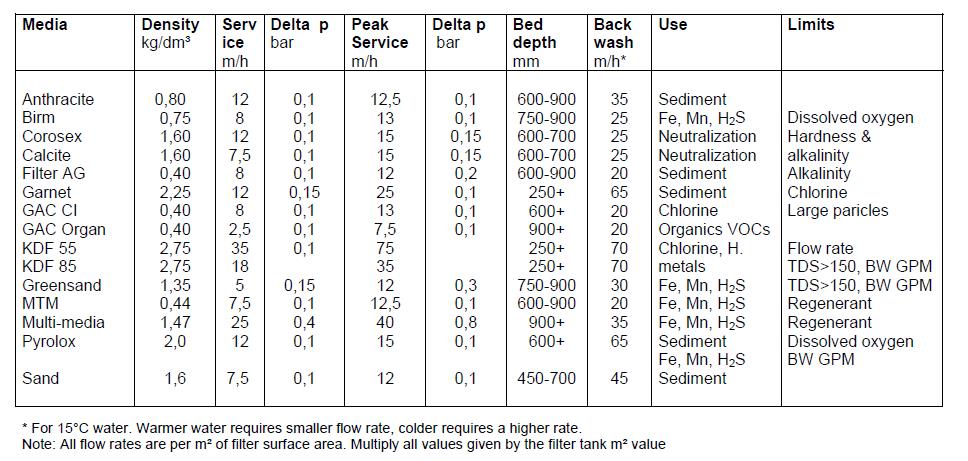

Για μια σύγκριση των μέσων φίλτρου, δείτε τον παρακάτω πίνακα. Υπάρχουν και άλλα μέσα που θα μπορούσαν να συμπεριληφθούν σε αυτήν τη λίστα, αλλά προσφέρει μια βασική κατανόηση των αρχών που εμπλέκονται.

Οι Βασικοί Μηχανισμοί

Η διήθηση γίνεται με δύο μηχανισμούς. Η πρώτη είναι απλώς μια ενέργεια κοσκινίσματος για την απομάκρυνση της αιωρούμενης ύλης. Οτιδήποτε μεγαλύτερο από τα κενά μεταξύ των κόκκων των μέσων παγιδεύεται. Τα μέσα φίλτρου αφαιρούν τα αιωρούμενα σωματίδια αλλά φιλτράρουν επίσης σε μέγεθος μικρότερο από τα κενά μεταξύ των κόκκων. Οι κόκκοι των μέσων φίλτρου είναι συνήθως στο 300-1. Μέγεθος 700 micron με κενά μεταξύ τους 25 - 500 micron. Η δυνατότητα φιλτραρίσματος κάτω από το πραγματικό μέγεθος του χώρου μεταξύ των σωματιδίων οφείλεται στην επιφάνεια του μέσου φίλτρου. Αυτή η διαδικασία επηρεάζεται από μια σειρά μεταβλητών, όπως η βαρυτική ρύθμιση, η διάχυση, η αναχαίτιση και η υδροδυναμική. Αυτές οι μεταβλητές επηρεάζονται με τη σειρά τους από φυσικές ιδιότητες όπως το μέγεθος του φίλτρου, ο ρυθμός διηθήματος, η θερμοκρασία του υγρού, η πυκνότητα, το μέγεθος και το σχήμα της αιωρούμενης ύλης. Επίσης, μην ξεχνάτε τις ηλεκτροστατικές απωστικές δυνάμεις και τις δυνάμεις του Van der Waal, όπου τα ηλεκτρόνια συσχετίζουν τη διπολική κίνηση των υποατομικών σωματιδίων που επηρεάζουν την έλξη. Επιπλέον, χρησιμοποιούμε μέσα φίλτρου που έχουν σχεδιαστεί με πρόσθετα χαρακτηριστικά, όπως οξείδωση, αναγωγή και εξουδετέρωση. Όλα τα μέσα φίλτρου απαιτούν αντίστροφη πλύση, μερικά χρησιμοποιούν αναγεννητικό και πολλά έχουν περιορισμούς ή απαιτήσεις σε συστατικά του νερού.

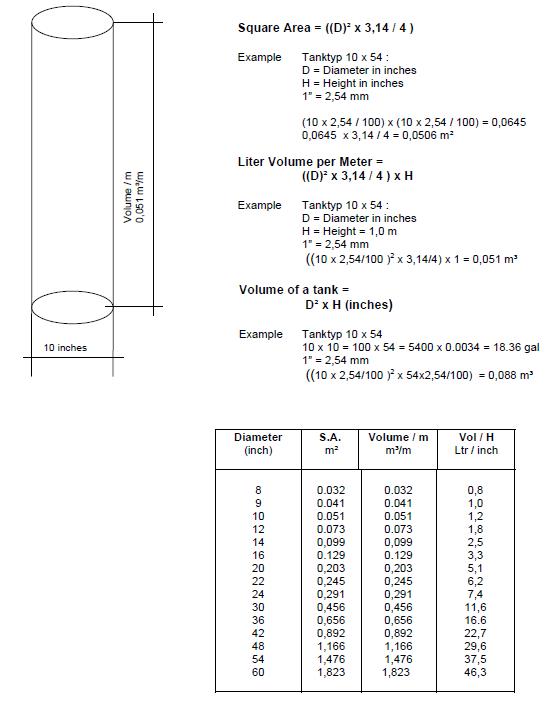

Ως συνέπεια της πολυπλοκότητας της διαδικασίας φιλτραρίσματος, οι ρυθμοί ροής υπηρεσιών στη βιβλιογραφία προϊόντων εκτιμώνται στην καλύτερη περίπτωση. Η ροή της υπηρεσίας πρέπει να ταιριάζει με τα κριτήρια προσρόφησης. Οι ρύποι στο νερό μπορεί να έχουν χαμηλή, μεσαία ή υψηλή επιφάνεια χαμηλής, μεσαίας ή μεγάλης επιφάνειας, επηρεάζοντας έτσι την ικανότητά τους να προσροφούν ορισμένα συστατικά. Εάν ο ρυθμός ροής υπερβαίνει τον ρυθμό σχεδιασμού, είναι πιθανό να υπάρχει κακή διήθηση. Οι ρυθμοί αντίστροφης πλύσης έχουν σχεδιαστεί για να ρευστοποιούν (ανυψώνουν) την κλίνη φίλτρου με βάση την πυκνότητα του μέσου φίλτρου. Οι χαμηλοί ρυθμοί αντίστροφης πλύσης έχουν ως αποτέλεσμα ατελή καθαρισμό του κρεβατιού και πρόωρη αστοχία του φίλτρου. Οι πολύ υψηλοί ρυθμοί αντίστροφης πλύσης μπορεί να έχουν ως αποτέλεσμα την απώλεια των μέσων φίλτρου.